- FläktGroup UK

- Legislation

- Low GWP

New ways in line with the F-Gas Directive

The F-Gas Directive (EU) 517/2014 has a major impact on the air conditioning industry. It steers the market towards low-carbon HVAC systems. Water-based air conditioning systems with low refrigeration charges and/or refrigerants with low GWP values can be considered particularly future-proof.

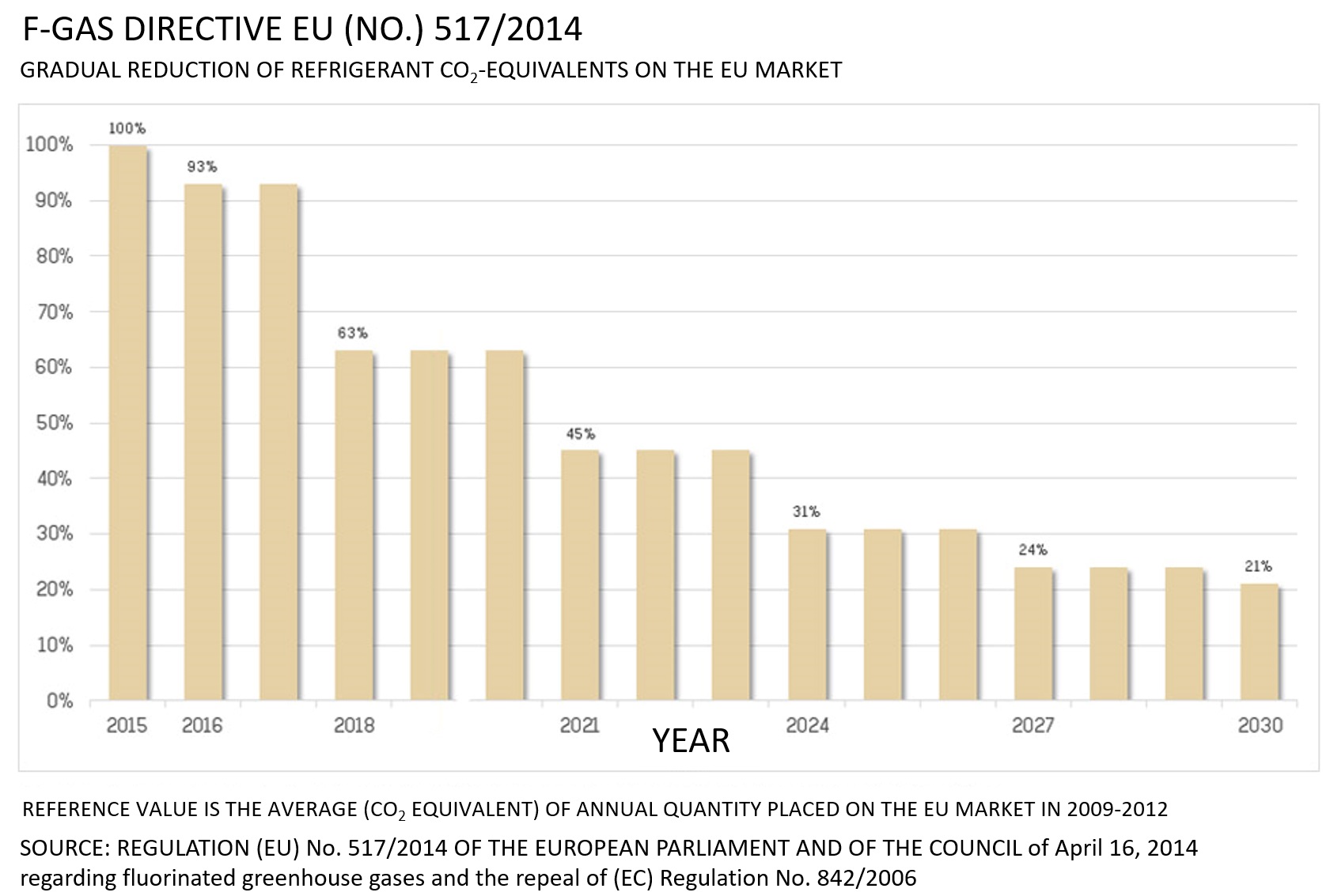

EU Regulation 517/2014, also known as the "F-Gas Directive", provides for a gradual phase-down of the CO2 equivalent of the refrigerants introduced into the EU market by 2030. CO2 equivalent is the product from the amount of refrigerant in kg and its global warming potential (GWP).

To meet the 21% quota in 2030 while continuing to meet the demand for refrigerants in the EU, it is mandatory to reduce the average GWP of the refrigerant mix placed on the market. High-GWP refrigerant is becoming scarce in the market, which led to a significant increase in the price of these refrigerants after the first major quota reduction at the beginning of 2018. Refrigerant with low GWP is not affected by such price jumps and are therefore considered to be particularly future-proof. Nevertheless, there are no prohibitions for conventional refrigerant R-134a (GWP 1430) or R-410A (GWP 2088) used in air conditioning technology when used in chillers or heat pumps. They are still used as a standard in some products for non-flammability. This includes, for example, indoor equipment such as water-cooled chillers, close control units for cooling server rooms or small air-cooled chillers and heat pumps up to 40 kW with very small refrigeration charges.

Due to the influences of the F-Gas Regulation and economic aspects, the market for larger chillers and heat pumps is moving from conventional HFC refrigerants to fourth-generation refrigerants, the so-called hydrofluorolefins (HFO), or mixtures of HFO and HFC refrigerants, also known as HFO-blends. Depending on the choice of refrigerant, the alternative solution moves in a voltage triangle between low GWP, low investment costs for the device and worsened combustibility properties.

For example, the alternative refrigerant for air conditioning applications is usually assigned to safety class A2L according to ISO 817. This means that the refrigerant has low flammability and therefore the relevant safety requirements from the respective operating instructions and in particular EN 378 must be observed.

The A2L refrigerant R-1234ze, also known as HFO-1234ze, is considered a replacement for R-134a in devices with screw compressors and impresses with its very low GWP value of 7.

The A2L refrigerant R-454B (GWP 466) is a newly developed HFO blend that is used as a replacement for R-410A in devices with scroll compressors. The mixture consists of R-32 and R-1234yf. The GWP value is 466, which means a reduction of 78%.

The A2L refrigerant R-454B (GWP 466) is a newly developed HFO blend that is used as a replacement for R-410A in devices with scroll compressors. The mixture consists of R-32 and R-1234yf. The GWP value is 466, which means a reduction of 78%.

An exception in terms of flammability is the HFO-Blend R-513A, which is available as a replacement for R134a and is assigned to safety class A1 and is therefore classified as non-flammable as R-134a and R-410A. The mixture consists of R-134a and R-1234yf and has a reduction of 56% with a GWP value of 631.

An exception in terms of flammability is the HFO-Blend R-513A, which is available as a replacement for R134a and is assigned to safety class A1 and is therefore classified as non-flammable as R-134a and R-410A. The mixture consists of R-134a and R-1234yf and has a reduction of 56% with a GWP value of 631.

In terms of investment costs, equipment with replacement refrigerants R-454B and R-513A can be classified as approximately neutral, since the available refrigeration capacities of the equipment are approximately identical due to the physical properties of the refrigerants compared to the use of the original refrigerants R-410A and R-134a respectively. The refrigerant R-1234ze, on the other hand, delivers significantly smaller volumetric outputs than R-134a, so larger components must be used to achieve the same cooling performance. This makes the devices significantly larger and the cost of the components increases. The ability to choose between R-513A and R-1234ze for devices with screw compressors offers the advantage of focusing either on an average GWP of 631 combined with low investment costs and no combustibility or on a very low GWP of 7 combined with higher investment costs and low flammability.

The air-cooled chillers of the FGAC product line and reversible air-water heat pumps from the FGAH product line from FläktGroup are available with the three low GWP variants mentioned above. They are factory filled with refrigerant and hermetically closed. The devices are intended for outdoor installation so that the circulating refrigerant is not in the building, but only outdoors. This is very easy to meet the necessary security measures. These include, for example, distance rules to roof hatches or air intakes. An elaborate safety consideration, as required for direct evaporating VRF systems with flammable A2L refrigerants, is saved, as it is impossible to escape refrigerant during leaking evaporators or pipeline connections in occupancy areas. Compliance with the maximum permitted refrigerant quantities and, if necessary, further safety measures are no longer required.

FläktGroup relies on the low GWP refrigerant R513A (GWP 631) with safety class A1 for the water-cooled chillers for internal installation of the FGWC product lines, so that it can be implemented in the technical room without stricter safety requirements. Devices of the GLWC product line with the proven refrigerants R-410A (GWP 2088) and R-134a (GWP 1430) are still used without restrictions due to the advantageous A1 classification.

FGAC / H (R-454B)

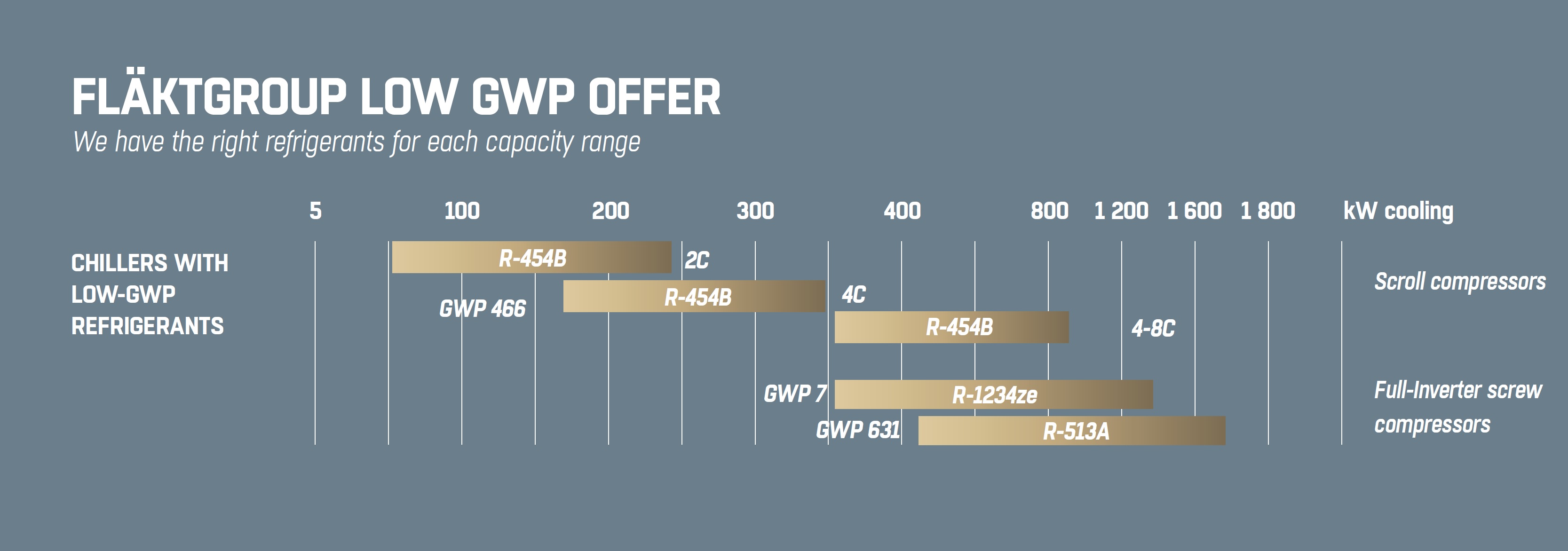

In the capacity range from 53 to 338 kW, FläktGroup offers FGAC chillers from 53 to 223 kW as well as reversible heat pumps of the FGAH series with scroll compressors and the low-GWP refrigerant R-454B. The devices are available in many variants, for example with built-in pumps and buffer storage.

Read more

FGAC (R-513A & R-1234ze)

In the larger capacity range from 380 kW to 1700 kW, FläktGroup relies on units with full inverter screw compressors for which the refrigerants R-513A or R-1234ze are available. When using R-1234ze, plus points are achieved in building certification programs. All devices are available with built-in pumps.

Read more

FGWC (R-513A)

In the capacity range from 530 to 1780 kW, FläktGroup offers water-cooled chillers of the FGWC product line that work with the refrigerant R-513A. The cooling output is identical to that of R-134a, but the efficiency is increased by 4%. Identical device components are used as they have proven themselves with R-134a. The devices are equipped with two double-rotor screw compressors from the quality brand Bitzer and an upstream inverter.

Read more