- FläktGroup

- Solutions

- Schools & Auditorium Ventilation

Schools & Auditorium Ventilation

HVAC ventilation requirements in schools require care and attention to achieve the best air comfort conditions for learning and developing.

Creating the best environment for learning

Educational facilities provide a variety of differing indoor spaces that all come with their own challenges.

When considering this applciation type we must consider the reduction of noisy distractions that would affect a young persons concentration. We also consider air temperature, draughts, odour control and in some cases where a building is large enough fire safety solutions for safe exit of a building. At FläktGroup we take these needs into consideration and have created solutions that manage the needs of small and large capacity schools and colleges, focusing on class room learning, gynamisums and even comfort in corridors between class time.

Ventilation of Auditoriums

Ventilating large rooms with variable occupancy

Large rooms with lots of volume pose specific challenges to a ventilation system. Large crowds, sometimes bringing outerwear, can produce large amounts of dust.

The variable capacity of a room must also be dimensioned to deliver enough fresh air that will ensure comfort when the room is nearly empty or crowded. Quiet moments during a concert or monologue might require almost complete silence in order that the audience can appreciate the full experience.

Business center/ Auditorium

Area 300 m2 Air volume +/- 800 l/s (100 persons)

Proposed solution

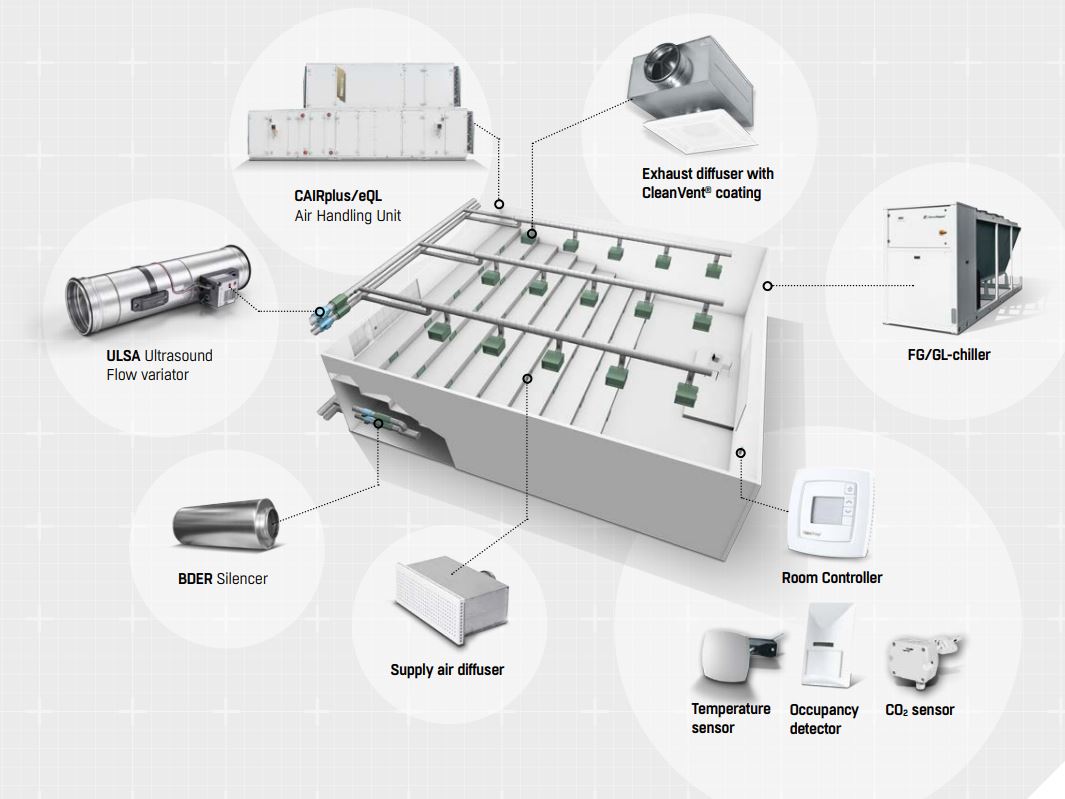

PROPOSED DESIGN FUNCTIONS

- CO2-, temperature and occupancy sensors monitor the room’s indoor air climate

- Room controller receives messages from the different room sensors and controls the VAV dampers

- Room’s ventilation system is constantly driven by demand controlled ventilation

OPTIVENT® ULTRA BENEFITS

- Dust resilient construction is needed for auditorium that contains a lot of fabric dust from people’s clothes

- Accurate air flow measuring and wide air flow range

- Silent ventilation is necessary during shows and recordings

- Reduced need for maintenance work that can disrupt daily activities

Planning Tips / Checklist

- Min air flow in the room: 150 l/s (floor area 300 m²)

- Max air flow in the room: 800 l/s (80 people) vs general rules

- Supply air duct: 2x ø 315 mm (v=5,13 m/swith max air flow)

- Exhaust air duct: 2x ø 315 mm (0,85 Pa/m)

- OPTIVENT® ULTRA: ULDA-5-315-1 for supply and exhaust (same size as duct)

- Silencer: BDER-44-031-090 for supply and exhaust (xx dB(A) right after silencer with q=100 l/s and ΔP=80Pa)

- Air pattern (diffuser DASH-100): max air velocity 0,1 m/s in the occupational zone with maximum air flow

Mass List: Business Center/Auditorium

Air management

- Optivent Ultra VAV-damper ULDA-5-315-1 (4 pcs)

- Silencer, length 900mm, BDER-44-031-090 (4 pcs)

Air diffusion

- Supply diffuser (80 pcs) integrated behind steps DASH-100-0

- Exhaust diffuser (16 pcs) with clean vent painting HPKH-160-6-C and ATTC-125-160-1 Automation systems

Automation systems

- Room Controller (Modbus connection) STRA-04

- Transformer STRZ-24-1

- CO2-sensor STRZ-18-1-2

- External temperature sensor STRZ-05-4

- PIR Occupancy detector STRZ-09-1

USE OUR SELECTION TOOLS

CONTACT OUR SALES TEAM

VIEW OUR REFERENCES

Products

-

CAIRplus AIR HANDLING UNIT

CAIRplus AIR HANDLING UNIT

- CAIRplus is the tailor-made premium range of modular air handling units for every customer requirement

- Environmentally-friendly design means an energy recovery system with high efficiency is available for every configuration

- Clean surfaces and ease of cleaning guarantee hygienic standards to VDI6022

- All units can be supplied with FläktGroup integrated controls ISYteq 4.0

- T2/TB2/L1/D1 Eurovent certified casing

-

eQL® AIR HANDLING UNIT

eQL® AIR HANDLING UNIT

- High degree of flexibility of functionality, configuration and materials

- Flexible and high efficiency energy recovery systems

- Optional service corridor

-

OPTIVENT® ULTRA - ULSA VAV DAMPER

OPTIVENT® ULTRA - ULSA VAV DAMPER

- Accurate air flow measurement

- No pressure loss nor noise of the air flow measurement

- Large air flow range

- Small influence of dust

-

Room controller

Room controller

- Energy saving functions such as free cooling and energy saving mode.

- Reliable operation with 4 separate positions.

- Easy installation thanks to separate basic plate for cable connections.

- Preprogrammed and simple reconfiguration via dipswitches.

-

FGAH 2020-2081 AG 1/2 (R454B, 53 -223 kW)

FGAH 2020-2081 AG 1/2 (R454B, 53 -223 kW)

- 1 refrigeration circuit with Tandem Scroll Compressor

- Excellent efficiency values, SCOP up to 4.2 (eta,s 166 %)

- High planning reliability, as compliant with ErP directive 813/2013 EU

- Standard, HE (high efficient) and SL units (super low noise) available

- Heating operating up to -15 °C ambient