- FläktGroup

- Selected References

- Rovaniemi Hospital

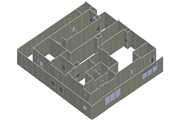

Rovaniemi Hospital

Lapland Central Hospital Expansion, Rovaniemi

Two new buildings and an extensive renovation construction project, the project completed in 2023.

In the project, new facilities will be implemented, e.g. for the emergency room, surgery and anesthesia unit and hospital pharmacy.

Minimization of the ecological footprint and overall economy of investment and use have been taken into account in the design and construction.

The new patient-oriented hospital complex serves the residents of all of Lapland.

The Solution from FläktGroup:

We delivered and installed 1105 m² of R-type sandwich wall panels, along with pharma glazing windows and hinged doors with an interlock system. We provided two types of transfer boxes as a convenient solution for transferring items between areas with different cleanliness classes, equipped with an interlock system. The delivery included 590 m² of RS Panel Ceiling, as well as 1960m2 of Inwall OT+ facing panels for ORs with lead protection 1+2mm.

Clean room solutions for hospital pharmacies and operating rooms, which include, among others:

- Sandwich wall panels R-type 1105 m2

- Inwall OT+ facing panels with lead protection 1+2mm 1960m2

- RS Panel Ceiling 590 m2

- Windows & hinged doors with interlock system

- Transfer boxes

- Grilles

- Sliding cabinets and hatches

- Space planning

- Lamp housings

- 29 m² refrigerator

- Clean room and commissioning measurements

- Support structures for operating room roof trusses

Expectations were met - and exceeded

The most critical thing for a hot hospital is the smooth treatment of the patient and efficient transitions from one phase of treatment to another. Functional, safe and healthy facilities are central to this. This delivery included many types of facilities, for example the operating theaters included one double theater and the pharmacy premises had different walk-in cabinet solutions. The delivery also included cold rooms , Rissanen opens up about the scope of the project.

The new clean rooms of the hospital pharmacy are about 10 times larger than before, and they contain their own rooms for all functions. This considerably reduces, for example, the risk of cross-contamination and makes it possible to manufacture completely new types of products. The new solutions would seem to have eased the problem areas that caused the project to be started. Cooperation with FläktGroup has also been smooth and flexible. The installation side of the clean room has handled its work in an exemplary manner. The installation team has acted proactively, which has made it possible to solve many problems at an early stage , pharmacist Niinikoski praises.

Rissanen also says that he has received a lot of positive feedback. AHMA* has fulfilled the expectations set for it both from the point of view of end users and other stakeholders.

- Feicon Oy, which performed the validation of the premises, said that the tightness of the premises is the best they have ever measured, he mentions.

The construction of the hot hospital of Lapland Central Hospital began in spring 2020, and the entire hospital expansion was completed in 2023.

*AMHA - A concept and term applicable to Finland only. Find out more here on our Finnish website:

Watch to find out more

FläktGroup Clean Room System Solutions for Pharma

FläktGroup Clean Room System Solutions for Surgery

FläktGroup Clean Room System Solutions for Hospital

Products used in Clean Room solutions

Products

-

Fresh Heaven MAXX LAMINAR AIRFLOW UNIT

Fresh Heaven MAXX LAMINAR AIRFLOW UNIT

- Size upon Customer’s demands

- Air delivered by AHU (FHM) or recirculation mode with power module (FHM P)

- H13, H14 or U15 filters with U-shaped or fluid gasket

- Casing in stainless-steel / steel in RAL 9010, height 450 mm (FHM) / 550 mm (FHM P)

- Various outlets (perforated stainless-steel / steel in RAL 9010, polyester fabric)

- Equipped with autonomous automatics (local control via Siemens LOGO! panel)

-

Fresh Breeze – FAN FILTER UNIT

Fresh Breeze – FAN FILTER UNIT

- Full area filtration

- Energy efficiency is ensured through EC fans

- Own production of HEPA and ULPA filters to perfectly match unit design

- Low initial pressure drop of filters

- Various air-outlet types

- Independent control unit

-

AIR SHOWER

AIR SHOWER

- Decontamination is performed by clearing off dust and dirt particles from bodies of clean room personnel

- Maximum efficiency through a high-velocity turbulent jet of clean air of 25 m/s

- Cleaning cycle activated by PIR-motion sensor, door blocking, and user control settings

- Filtration using a pre-filter and HEPA filter

- Up to 3 rooms can be interconnected

-

DOORS & WINDOWS

DOORS & WINDOWS

- An automatic drop-down seal integrated into the door leaf enhances the air-tightness of a door

- Being flush with sandwich wall partitions ensures easy maintenance and flawless disinfection

- An interlock system equipped with signaling units prevents both doors in an airlock room from being opened simultaneously, effectively reducing the risk of contamination

- Doors can be opened manually or automatically with automatic drive

- Transfer doors are used as partitions of transfer boxes (passive or with filtered airflow)

- Accessories available include automatic drives, door closers, mirrors, windows with sunblinds, windows made from float glass or safety glass (ESG, VSG), automatic drop-down seals, stainless-steel kick plates, electromechanical and electromagnetic locks, signaling panels (semaphore), and many more.

-

EHSD CIRCULAR FLOW VARIATOR

EHSD CIRCULAR FLOW VARIATOR

- Easy and Quick Selection

- Insulated casing

- Integrated orifice plate for air measurement

- FG compact controller as standard

-

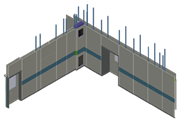

SANDWICH PANELS

SANDWICH PANELS

- The panels have a sandwich structure (two steel sheets with thermal insulation between them), with painted or stainless-steel sheet facing

- Custom colors and various core options are possible with minimal particle release

- R-panels 62 mm thick, M-panels and Me-panels are 60 mm thick

- Matching flush glassed-in panels (non-opening windows) and doors are available

- All joints are sealed by permanently elastic silicone in a color closely matching the panel color

- Round connections to the floor, suspended ceiling, and inner corners (Radius profiles system) are available

- The panels offer easy maintenance, effective sanitation, and resistance to disinfectants

- They ensure tightness to maintain over pressure or under pressure in the clean room

-

Inwall FACINGS

Inwall FACINGS

- The ideal solution for adapting existing rooms into clean rooms.

- Easy and quick fixation to structural walls

- All panels are prefabricated – minimal adjustments on site

- All joints sealed with silicone

- Panels connected via conductive cables are grounded to the earthing point

-

EXHAUST-AIR COMPONENTS

EXHAUST-AIR COMPONENTS

- Reliable ventilation of anesthetic gases, particles and exhaust of room air burdened with microbes

- Various choices of extract-air components

- Seamless integration of extract-air components in all types of wall panels and facings

-

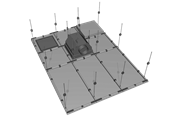

CEILINGS

CEILINGS

- LS ceiling – clip-in light ceiling

- KS ceiling – grid cassette ceiling

- KSH ceiling – walkable Alucore grid ceiling

- RS ceiling – walkable sandwich panel ceiling.

- A minimum number of particles is released from the panel surface

- Ease of installation, cleaning and sanitation, resistance to conventional disinfectants

- Joints between cassettes are sealed using permanently elastic sealant

-

eQ MASTER® AIR HANDLING UNIT

eQ MASTER® AIR HANDLING UNIT

- Tailor made for customer needs

- Energy Efficient and optimized with integrated control

- Large variety of high efficiency components

-

CGx Ceiling Air Outlet HEPA FILTER DIFFUSORS

CGx Ceiling Air Outlet HEPA FILTER DIFFUSORS

- Used in pharmaceutical industry, laboratories, hospitals, microbiology, electronic industry, and food industry

- Easy integration in all types of FläktGroup suspended ceilings

- Filter classes H13 to U15 in an aluminum frame, with dry or fluid seal

- For turbulent displacement flow

- Integrated pressure-gauge connection for monitoring pressure drop

- Tube for applying test aerosol (measuring of concentration)

-

CAIRplus AIR HANDLING UNIT

CAIRplus AIR HANDLING UNIT

- CAIRplus is the tailor-made premium range of modular air handling units for every customer requirement

- Environmentally-friendly design means an energy recovery system with high efficiency is available for every configuration

- Clean surfaces and ease of cleaning guarantee hygienic standards to VDI6022

- All units can be supplied with FläktGroup integrated controls ISYteq 4.0

- T2/TB2/L1/D1 Eurovent certified casing

-

GLFC 2150-2600 DA2 (286 - 1212 kW)

GLFC 2150-2600 DA2 (286 - 1212 kW)

- Version with 2 screw compressors

- SEPR-HT values up to 6.3

- ErP 2021 compliant with EU 2016/2281

- Available as Standard or Super-Low noise (SL) versions